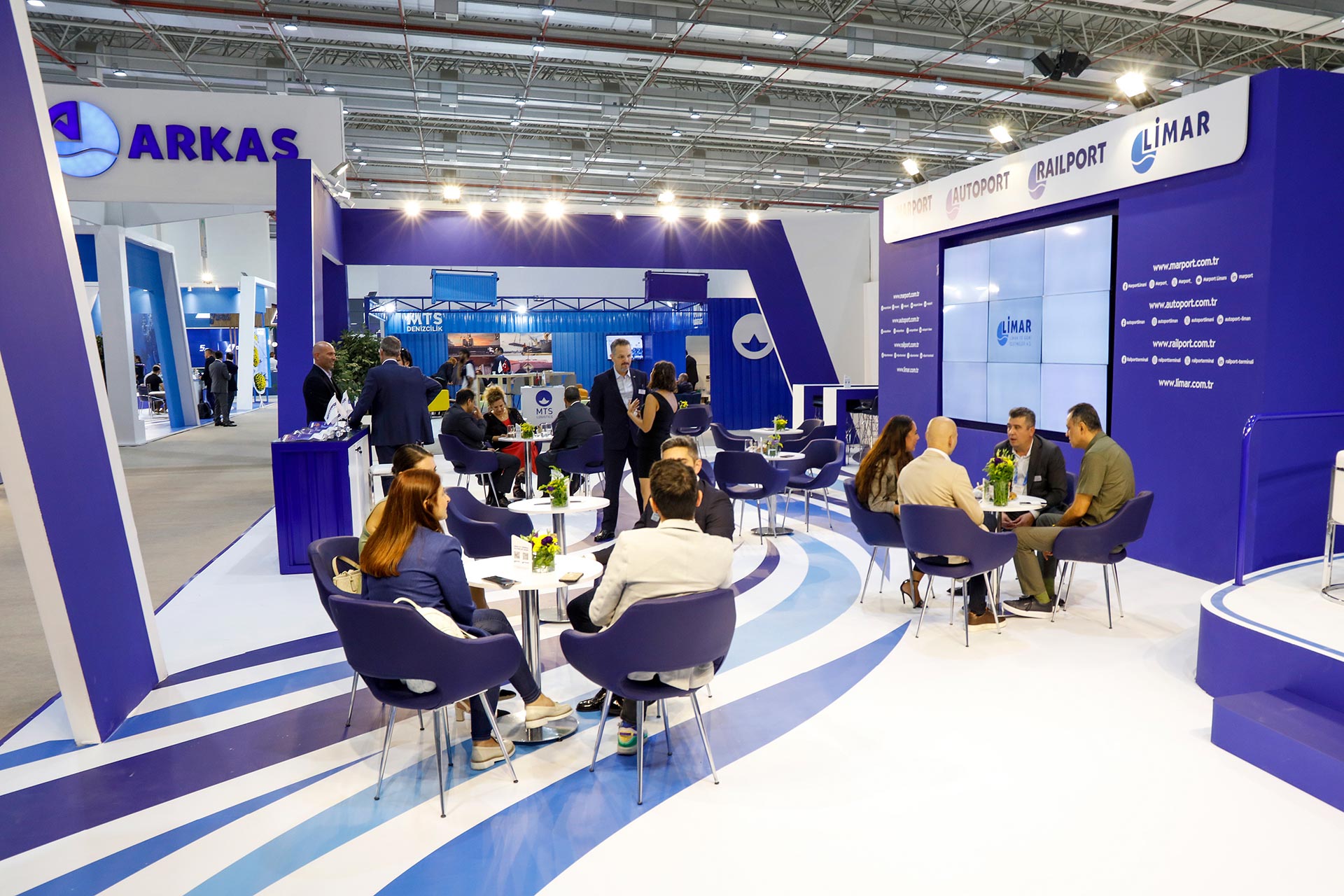

Arkas took center stage at the Logistech Fair, held from September 27th to September 29th, 2023, showcasing its core business divisions with its group companies Arkas Shipping, Logistics, and Port and Terminal Operators, while introducing the latest innovations in its services.

The Logistech Logistics, Warehousing and Technologies Fair, organized for the second time by Izmir Fair Services Culture and Art Affairs Trade Inc. (IZFAŞ), has offered participants and visitors an immersive experience, bringing together the entire supply and demand chain of the logistics industry.

With approximately 8,300 employees working at its 63 companies, Arkas presented its integrated service chain and innovations through the group companies of Arkas Maritime Group, Logistics Group, and Port and Terminal Services Group representing its core business divisions: Arkas Line, Arkas Logistics, Shipeedy Logistics, Arkas Rail, Marport Autoport, Limar, and Railport. On the first day of the fair, Izmir Metropolitan Municipality Mayor Tunç Soyer visited the stands, and on the second day, Bernard Arkas, Vice President of Arkas Holding, also paid a visit.

Green Transportation at Arkas Line

Can Atalay, CEO of Arkas Line, has provided insights into Arkas Line, saying: “Leveraging Arkas Holding’s 76 years of international transportation experience, Arkas Line boasts Türkiye’s largest container vessel fleet with 47 vessels today. We provide regular line transportation services between Black Sea, Mediterranean, and West African ports on a weekly basis with container vessels that we operate ourselves.”

Atalay added, “In 2023, we prioritized enhancing the performance of our existing services. We have started adding additional vessels to certain routes where we struggled to provide weekly services. These additional vessels will create approximately 30,000 TEUs of new capacity annually. We are also continuing our efforts to establish new routes, and we will announce our new route at the end of the year.

He continued, “Various global factors will bring changes to supply chains. New concepts, which have entered the industry’s vocabulary such as “friendshoring,” “allyshoring” (sourcing production and resources from allied countries), “reshoring” (bringing production back to the home country), and “nearshoring” (sourcing from nearby countries), all are the prelude of this change. With its strategic geographical location and high-quality production, Türkiye has the potential to attract numerous investments. Increased production will also invigorate the Turkish maritime industry. However, investments, both at sea and on land, must be made to commence now to seize this opportunity.”

“At Arkas Line, we continue to renew the vessels in our fleet in line with our long-term sustainability and emission goals. In this regard, our agenda includes the renewal of vessels in our fleet, especially those with low CII performance, with alternative vessels compatible with eco-design and new fuel technologies. Our technical and operational improvements will help reduce our environmental impact while achieving our goal of leaving a more sustainable world for future generations. Additionally, we are considering ordering vessels that use alternative fuels, but due to uncertainties in fuel supply and the long investment horizons of 20 years, Arkas Line is still in the process of evaluating the ‘best’ options,” Atalay stated. He also mentioned that Arkas has joined the UN Global Compact, aligning with their sustainability goals.

The sustainability agenda of Arkas Maritime Group includes key elements such as carbon neutrality, supply chain sustainability, employee motivation, and community engagement. One project stands out, especially in times when water conservation is crucial. The Arkas Turmepa II waste collection boat project, initiated in collaboration with TURMEPA in 2006, has collected 2,120,000 liters of wastewater to date, ensuring the cleanliness of 17 million liters of seawater.

Arkas Logistics is in the International Arena

With a robust organizational structure in Türkiye, known as one of the world’s most significant production centers, Arkas Logistics continues to invest and grow. Onur Göçmez, President of Arkas Holding Logistics Group, stated, “We are increasing our offices in some of the world’s most important markets. With investments that support end-to-end logistics from the United States to China, we are strengthening our presence in global markets. In March 2023, we opened a 3,000 square meter closed warehouse and office in New Jersey, USA, offering door-to-door FTL/LTL final transportation, storage, and customs clearance services to every region of the country. We also provide logistics solutions for shipments from global markets to the United States. Another significant investment for our logistics group is India. India, which stands out in new trade corridors, will have a significant impact on our becoming a global player. We have also opened an office in Romania, where the largest number of Turkish companies operate in Europe. We will be active in both logistics activities between Türkiye and Romania and between Romania and European countries. Furthermore, with our office in Poland, the largest logistics market and export centers in Europe, we will build logistics bridges between Türkiye-Poland, Europe-Poland, USA-Poland, and the Far East-Poland.”

Expanding Intermodal Services in Europe

Onur Göçmez shared that Arkas Logistics is expanding its intermodal services in Europe. He said, “We recently signed a service agreement for intermodal transportation between Duisport and Hupac. Reciprocal train services are organized between Halkalı and Duisport terminal, facilitating freight transport to various countries in Europe, including Germany, Belgium, and the Netherlands. Additionally, in terms of sustainability, we are also offering green logistics solutions to our manufacturers and exporters. We are aware of the adverse effects of the climate crisis in our investments, and we are taking steps accordingly.”

Sustainable Logistics with Arkas Rail

Göçmez continued, “Another company that excites us for sustainable logistics and for which we are preparing is Arkas Rail. In 2025, we will receive 5 locomotives. These locomotives, acquired with an investment of $38.5 million, can operate on electricity. These eco-friendly locomotives will transport import and export containers from Türkiye’s industrial cities to ports. This will provide our customers with a lower-cost, faster, and safer transportation service. We are also continuing to provide seaway LCL shipping through Shipeedy Logistics, serving e-commerce platforms and SMEs.”

Digitalization Leads to Efficiency

Highlighting the growing need for technological advancements right after the pandemic and their solutions in this field, Göçmez said, “Arkas Logistics and Shipeedy Logistics websites have been updated. Users can now receive instant price quotes and submit requests. With the Ar-cell digital tracking system, both driver and vehicle data can be monitored in real time. Thanks to this system, we achieved savings of approximately TRY 8 million in fuel costs from August of last year to August of this year. Moreover, we have achieved a 74% improvement in speed violations. Digitalization has allowed us to make tangible gains in environmental and safety aspects. With the ‘Flow Control System’ developed by Ar-cell, the temperature of products in reefer containers can be continuously and instantly monitored from loading to delivery. In the next step, we have integrated this system into the Ar-cell mobile application, allowing our customers to track the entire process with digital verification.”

Further Investments in Port and Terminal Services

Özgür Kalelioğlu, Arkas Holding Port and Terminal Services Group President, said, “As Marport, we continue to pioneer in Türkiye with a new-generation terminal operating system and leading investments. As part of the Modernization and Expansion Project, which started in 2021 and is aimed to be completed by the end of 2024, we increased the length of quay number 7 from 360 meters to 450 meters. We have started reinforcement works on quay number 6. When the project is completed, we will also serve mega vessels at this quay with a quay length of 400 meters. Additionally, with the four new SSG orders we placed in 2023, we aim to increase the number of SSGs from 10 to 14, planning to provide SSG services at all quays.”

Kalelioğlu continued, “On the other hand, our investment in Railport, positioned as a new Intermodal Logistics Terminal in the East-West trade corridor in partnership with Duisport, continues. Covering a total area of 337,000 square meters, Railport will connect Asia and Europe via the Baku-Tbilisi-Kars railway and European railways, serving as a bridge for transport between Asia and Europe, Europe and the Balkans, and Central Asian (CIS) countries. This investment will introduce a new service approach that provides cost advantages, respects the environment, offers advantages in delivery times, and, most importantly, adds significant value to our country’s economy.”

Regarding Limar, one of the Arkas Group companies which became the first company to invest in the port industry in 1996, Kalelioğlu said, “While providing fast, safe, and economical port services with our own teams and equipment at 12 different ports in Türkiye, we also offer our customers the easiest solutions with the software that we specially developed for this service.”

He added, “For Autoport, Türkiye’s ‘first automotive terminal,’ which was built to meet the private terminal needs of the automotive sector, located in Eastern and Southern Marmara and strategically positioned for all automotive manufacturers and distributors, we have expanded our terminal area from 160,000 m2 to 243,000 m2 in the process that began in 2021. As part of the ongoing Modernization and Expansion Project, we will increase the terminal area to 403,000 m2 and our total vessel berthing length to 850 meters by the end of 2026. Our PDI facility that is integrated with the terminal, with an annual capacity of 200,000 vehicles and low carbon emissions, started its operations in 2022. Additionally, we have increased our capacity in this area with new warehouse investments specially designed to meet the needs of the sector.”